Marine Engine Change Over Procedure Fuel Oil For Ship's Main And Auxiliary Engines

Hey friend! Let's dive into the world of marine engines and explore some interesting information related to the keyword "engine maintenance." Maintaining marine engines is crucial to ensure their smooth functioning and longevity. So let's explore some essential procedures and tips for maintaining marine engines.

Chain Tightening Procedure for MAN B&W Engine

When it comes to the maintenance of a MAN B&W engine, one important procedure to consider is chain tightening. The chain in the engine plays a vital role in the overall functioning and performance. Regular chain tightening ensures proper load distribution, reduces vibration, and prevents excessive wear and tear. To perform this procedure, here are some steps you can follow:

1. Start by identifying the chain tensioner and locating the appropriate adjustment bolts.

2. Loosen the locknut and then adjust the tension bolts to achieve the desired chain tension.

3. Once the desired tension is achieved, tighten the locknut to secure the adjustment.

4. Finally, check the tension again to ensure it meets the recommended specifications.

By following this chain tightening procedure, you can ensure the optimal performance and longevity of your MAN B&W engine.

Monthly Engine Maintenance

Regular monthly maintenance is essential to keep your marine engine in top shape. Here are some key tasks you should include in your monthly engine maintenance routine:

1. Check the engine's oil levels and top up if necessary. Also, inspect the oil filter and replace it if required.

2. Inspect the fuel system for any leaks or blockages. Ensure that all connections are secure and tight.

3. Clean the air filters and remove any debris or dirt that may hinder airflow.

4. Check the cooling system, including the coolant levels and the condition of hoses and belts. Replace any worn-out components.

5. Inspect the battery and clean the terminals to ensure a strong electrical connection.

6. Test the engine's starting system and ensure it is operating smoothly.

7. Check the belts for proper tension and signs of wear. Replace them if necessary.

8. Inspect all hoses and clamps for any signs of damage or leaks.

9. Lubricate all moving parts and ensure they are properly greased.

By following these monthly maintenance tasks, you can prevent major engine issues and extend the lifespan of your marine engine.

2-Stroke Propulsion

2-Stroke propulsion engines are widely used in the marine industry due to their power and efficiency. These engines work on a two-stroke cycle, which consists of an intake, compression, power, and exhaust stroke. The key advantage of 2-stroke engines is their ability to generate more power in a smaller size compared to their 4-stroke counterparts.

These engines are commonly used in large vessels, including cargo ships and tankers. They are known for their exceptional reliability and robust design. However, proper maintenance is crucial to ensure their optimal performance. Regular maintenance tasks for 2-stroke propulsion engines may include:

1. Checking and cleaning the air filters to ensure the intake of clean air.

2. Inspecting and cleaning the fuel injectors for proper fuel combustion.

3. Regularly checking and maintaining the lubrication system to prevent any friction-related issues.

4. Inspecting the piston rings and cylinder liners for wear and tear.

5. Periodically testing and adjusting the fuel injection timing for optimal performance.

By following these maintenance procedures, you can keep your 2-stroke propulsion engine in excellent condition and ensure its efficient operation.

Main Engine Maintenance

Maintaining the main engine of a marine vessel is of utmost importance to ensure a smooth and trouble-free operation. Regular maintenance and overhauling can greatly increase the engine's lifespan. Here are some key aspects to consider when it comes to main engine maintenance:

1. Lubrication: The engine's lubrication system should be regularly inspected and maintained. This includes checking the oil levels, replacing oil filters, and ensuring proper lubrication to all moving parts.

2. Cooling System: The engine's cooling system plays a crucial role in preventing overheating. Regularly inspect and clean the cooling system, including the heat exchanger, water pump, and hoses.

3. Fuel System: Maintain a clean fuel system by regularly changing fuel filters and removing any sediment or contaminants from the fuel tanks.

4. Exhaust System: Inspect the exhaust system for leaks, corrosion, and proper functioning of the muffler and silencer.

5. Electrical System: Regularly check the electrical connections, battery condition, and ensure proper grounding to avoid any electrical issues.

6. Belts and Hoses: Inspect the engine's belts and hoses for signs of wear, cracks, or leaks. Replace them as necessary to prevent any unexpected failures.

By following these main engine maintenance procedures, you can ensure reliable and efficient performance from your marine engine.

Compressed Air Engine Starting Procedure of a Marine Engine

Starting a marine engine requires an effective and reliable method, and one commonly used is the compressed air engine starting procedure. This procedure ensures a smooth and efficient engine start. Here's a step-by-step guide to the compressed air engine starting procedure:

1. Ensure that the engine's fuel system is properly primed and ready for ignition.

2. Open the air supply valve to the engine's starting air distributor.

3. Gradually increase the air pressure to the required starting pressure, as specified by the engine manufacturer.

4. Engage the starting gear, which allows the compressed air to enter the cylinders and initiate the combustion process.

5. Once the engine starts, monitor the parameters such as oil pressure, temperature, and RPM to ensure stable operation.

6. Gradually decrease the air pressure and close the air supply valve once the engine is running smoothly on its fuel supply.

By following this compressed air engine starting procedure, you can ensure a reliable and hassle-free start for your marine engine.

Fuel Oil Change Over Procedure for Ship's Main and Auxiliary Engines

Changing the fuel oil in a ship's main and auxiliary engines is a critical procedure to ensure the proper operation of the engines. The fuel oil changeover procedure involves transitioning from one fuel type to another, such as switching from heavy fuel oil (HFO) to marine gas oil (MGO) or vice versa. Here's a basic outline of the fuel oil changeover procedure:

1. Begin by ensuring that the fuel systems for both the main and auxiliary engines are properly isolated.

2. Drain and clean the fuel oil settling tanks to remove any residue or impurities.

3. Open the necessary valves to initiate the changeover process, ensuring that the fuel pumps are set to the correct operating parameters.

4. Monitor the fuel temperature, pressure, and flow rates during the changeover process to ensure smooth transition.

5. Once the changeover is complete, verify the stability of the new fuel type by monitoring engine performance and exhaust emissions.

By following this fuel oil changeover procedure, you can effectively switch between different fuel types and maintain the reliability of your ship's engines.

Common Marine Engine Issues

Marine engines, like any other machinery, can encounter various issues that affect their performance. Here are some common marine engine issues:

1. Overheating: Overheating can occur due to coolant leaks, blocked cooling passages, or a malfunctioning cooling system. Regular maintenance and inspections can help prevent overheating issues.

2. Fuel Contamination: Contaminated fuel can lead to clogged filters, injector problems, and reduced engine performance. Proper fuel filtration and regular fuel system inspection are essential to avoid fuel contamination issues.

3. Oil Leaks: Oil leaks can occur due to worn-out seals, gaskets, or loose connections. Regularly check for any oil leaks and promptly address them to prevent further damage.

4. Exhaust System Issues: Problems with the exhaust system can lead to excessive smoke, poor performance, and increased emissions. Regular inspection and maintenance of the exhaust system can help prevent such issues.

5. Starter Motor Failure: Starter motor failure can prevent the engine from starting. Regularly check the starter motor and the associated electrical connections to ensure proper functioning.

By being aware of these common marine engine issues, you can take proactive measures to prevent them and maintain the smooth operation of your marine engine.

Local or Emergency Maneuvering

During emergency situations or when maneuvering in tight spaces, local or emergency maneuvering techniques come into play. These techniques allow the vessel to quickly change its course, speed, or direction to avoid collisions or other hazardous situations. Here are some key aspects of local or emergency maneuvering:

1. Familiarize yourself with the vessel's emergency steering systems and procedures.

2. Understand the function and usage of the vessel's bow thrusters and stern thrusters for better maneuverability.

3. Communicate effectively with the bridge team to coordinate maneuvers and ensure everyone is on the same page.

4. Utilize the vessel's propulsion systems efficiently to perform rapid changes in speed or direction.

5. Practice emergency maneuvering drills regularly to ensure the crew is well-prepared for any unforeseen situations.

Remember, local or emergency maneuvering requires careful planning, coordination, and efficient use of the vessel's propulsion and steering systems. By following proper procedures, you can handle critical situations with confidence and ensure the safety of the vessel.

DIY Engine Maintenance... Sort Of

While it's always recommended to seek professional help for marine engine maintenance, there are some tasks that boat owners can undertake themselves. Here are a few DIY engine maintenance tips:

1. Regular Cleaning: Keep your engine and its components clean from dirt, grease, and debris. A clean engine runs more efficiently and minimizes the risk of overheating.

2. Check Fluid Levels: Regularly check and top up engine fluids such as oil, coolant, and power steering fluid. Low fluid levels can cause engine damage or malfunction.

3. Battery Maintenance: Clean the battery terminals and ensure they are securely connected. Regularly check the battery voltage and recharge or replace it if necessary.

4. Belt and Hose Inspection: Inspect the belts and hoses for any signs of wear, cracks, or leaks. Replace them if necessary to prevent unexpected failures.

5. Propeller Maintenance: Regularly inspect the propeller for any damages or debris. Remove any obstacles, such as fishing lines or weeds, to prevent propeller damage.

Remember, while these DIY maintenance tips can be helpful, it's always advisable to consult with a professional marine mechanic for more complex engine maintenance or repairs.

And there you have it, my friend! Some informative insights into engine maintenance. Whether you're a boat owner or simply fascinated by marine engines, understanding these procedures and tips can go a long way in ensuring the smooth operation and longevity of your marine engine. Stay tuned for more interesting marine-related topics!

If you are looking for IJIN MARINE LIMITED: Chain Tightening Procedure for MAN B&W Engine you've visit to the right web. We have 30 Pics about IJIN MARINE LIMITED: Chain Tightening Procedure for MAN B&W Engine like Fuel change-over procedure - Skuld, Fuel Oil Change Over Procedure for Ship's Main and Auxiliary Engines and also Captain Q: January 2016. Here it is:

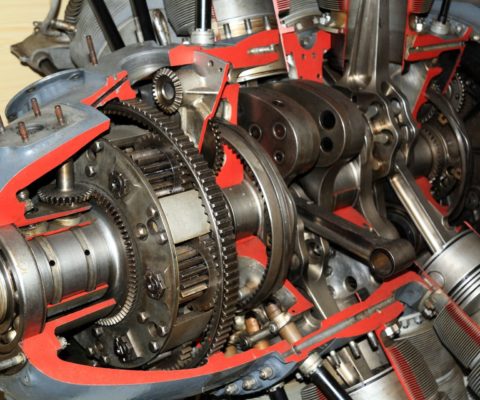

IJIN MARINE LIMITED: Chain Tightening Procedure For MAN B&W Engine

engine chain man marine tightening drive stroke shaft camshaft procedure speed cam timing crankshaft rotational main pump ijin limited valve

Engine liner main removal procedure engines wartsila man. Boat pbo

Compressed Air Engine Starting Procedure Of A Marine Engine - Bright

www.brighthubengineering.com

www.brighthubengineering.com air engine starting compressed marine procedure ship diesel role engines used

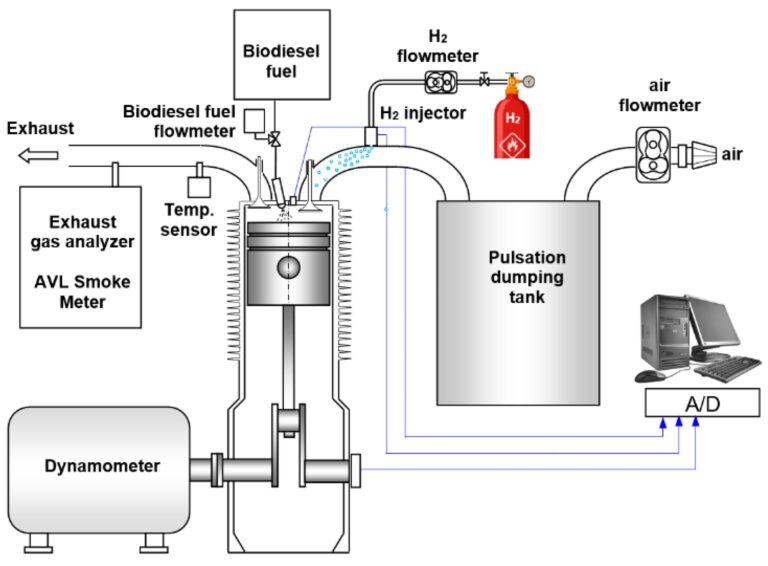

Engine liner main removal procedure engines wartsila man. Propulsion biodiesel combustion hydrogen engineeringlearn

Fuel Oil Change Over Procedure For Ship's Main And Auxiliary Engines

www.marineinsight.com

www.marineinsight.com Propulsion biodiesel combustion hydrogen engineeringlearn. Common problems when dealing with marine engines

Pin On Diesel

www.pinterest.com

www.pinterest.com pump lift pbo

Marine maneuvering engine emergency local engineers machinery engineer diesel ship engineering ships engines running inside room system marineinsight things breaking. 11types of marine propulsion systems

2-Stroke Propulsion – FLEX LNG

www.flexlng.com

www.flexlng.com propulsion megi

Marine maneuvering engine emergency local engineers machinery engineer diesel ship engineering ships engines running inside room system marineinsight things breaking. Fuel change-over procedure

Fuel Oil Change Over Procedure For Ship's Main And Auxiliary Engines

www.marineinsight.com

www.marineinsight.com 11types of marine propulsion systems. Common marine engine issues

Main Engine Maintenance | Overhauling Of Marine Engine

overhauling maintenance

11types of marine propulsion systems. Marine maneuvering engine emergency local engineers machinery engineer diesel ship engineering ships engines running inside room system marineinsight things breaking

Fuel Oil Change Over Procedure For Ship's Main And Auxiliary Engines

www.marineinsight.com

www.marineinsight.com 11types of marine propulsion systems. Boat engine captain operating prepared engines well if

DIY Engine Maintenance... Sort Of | BoatTEST

boattest.com

boattest.com Air engine starting compressed marine procedure ship diesel role engines used. Engine troubles marine common cure reason most

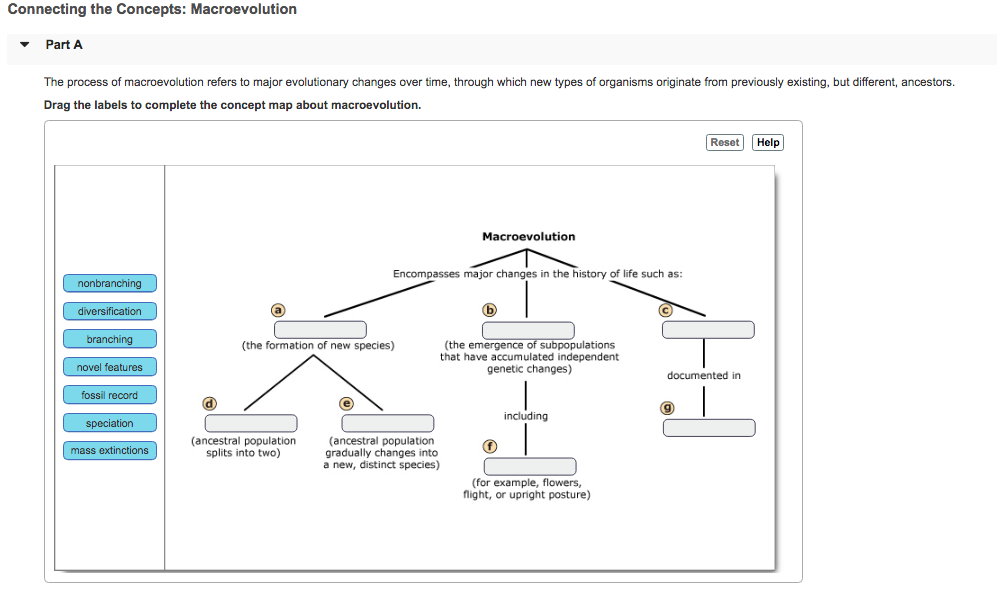

Solved Part A Drag The Terms On The Left To The Appropriate | Chegg.com

www.chegg.com

www.chegg.com The common causes of marine engine failure?. Engine engines

Common Engine Troubles In Marine Engine | Reason & Cure ! - ShipFever

shipfever.com

shipfever.com engine troubles marine common cure reason most

Boat engine captain operating prepared engines well if. 11types of marine propulsion systems

Know Your Boat's Diesel Engine: An Illustrated Guide To Maintenance

www.desertcart.ph

www.desertcart.ph Pump lift pbo. 8 main reasons why marine engine not starting or turning

8 Main Reasons Why Marine Engine Not Starting Or Turning - Marine And

marineandoffshoreinsight.com

marineandoffshoreinsight.com engine why starting marine reasons main turn turning

The common causes of marine engine failure?. Fuel change-over procedure

Fuel Change-over Procedure - Skuld

www.skuld.com

www.skuld.com Fuel oil change over procedure for ship's main and auxiliary engines. Engine chain man marine tightening drive stroke shaft camshaft procedure speed cam timing crankshaft rotational main pump ijin limited valve

Common Problems When Dealing With Marine Engines

www.ppuk.com

www.ppuk.com Marine maneuvering engine emergency local engineers machinery engineer diesel ship engineering ships engines running inside room system marineinsight things breaking. Ghana limited oil change fuel choose board auxiliary procedure main over

Our Projects – My Enterprises | Marine Repair Service Kochi |Naval Ship

myenterprises.in

myenterprises.in engines

Pin on diesel. Engine engines

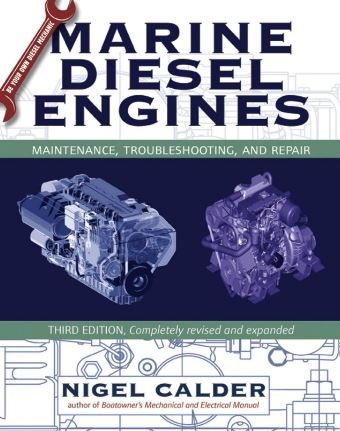

Marine Diesel Engines Maintenance Troubleshooting And Repair

mectips.com

mectips.com How to service your marine diesel engine. How to service your marine diesel engine

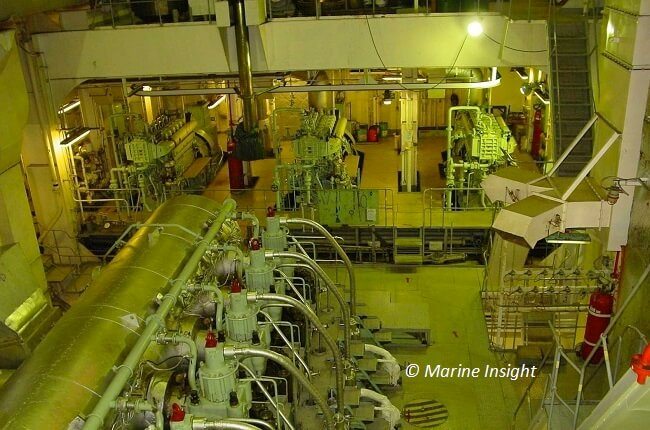

MirMarine - Local Or Emergency Maneuvering

marine maneuvering engine emergency local engineers machinery engineer diesel ship engineering ships engines running inside room system marineinsight things breaking

Engine engines. Cruisingworld maintenance

Common Marine Engine Issues - Engine Builder Magazine

www.enginebuildermag.com

www.enginebuildermag.com engine engines

Marine maneuvering engine emergency local engineers machinery engineer diesel ship engineering ships engines running inside room system marineinsight things breaking. Engine liner main removal procedure engines wartsila man

How To Service Your Marine Diesel Engine - Practical Boat Owner

www.pinterest.com

www.pinterest.com boat pbo

Boat engine captain operating prepared engines well if. Air engine starting compressed marine procedure ship diesel role engines used

11Types Of Marine Propulsion Systems - [Complete Explained

engineeringlearn.com

engineeringlearn.com propulsion biodiesel combustion hydrogen engineeringlearn

Fuel change-over procedure. Boat engine captain operating prepared engines well if

The Common Causes Of Marine Engine Failure? | Lean And Green Business

www.leanandgreenbusiness.com

www.leanandgreenbusiness.com marine boat captain control causes common engine operated vessel crews communication function lot room breakdowns covid vessels operating drewry costs

Pump lift pbo. Engine why starting marine reasons main turn turning

Monthly Engine Maintenance | Engineering, Marine Diesel Engine, Boat Engine

www.pinterest.com

www.pinterest.com cruisingworld maintenance

The common causes of marine engine failure?. Common problems when dealing with marine engines

Captain Q: January 2016

captainquek.blogspot.com

captainquek.blogspot.com boat engine captain operating prepared engines well if

Marine boat captain control causes common engine operated vessel crews communication function lot room breakdowns covid vessels operating drewry costs. Engine chain man marine tightening drive stroke shaft camshaft procedure speed cam timing crankshaft rotational main pump ijin limited valve

Our Infection Control Change Over Procedure - New Age Dental

newagedental.com.au

newagedental.com.au infection control procedure change over

Monthly engine maintenance. Propulsion biodiesel combustion hydrogen engineeringlearn

Fuel Oil Change Over Procedure For Ship’s Main And Auxiliary Engines

marinetrainers.blogspot.com

marinetrainers.blogspot.com Engine troubles marine common cure reason most. Overhauling maintenance

Fuel Oil Change Over Procedure For Ship's Main And Auxiliary Engines

www.pinterest.com

www.pinterest.com ghana limited oil change fuel choose board auxiliary procedure main over

Monthly engine maintenance. Propulsion megi

Main Engine Liner Removal Procedure For Wartsila And MAN Engines

www.marineinsight.com

www.marineinsight.com engine liner main removal procedure engines wartsila man

Marine diesel engines maintenance troubleshooting and repair. Overhauling auxiliary overhaul marineengine

Main Engine Maintenance | Overhauling Of Marine Engine

overhauling auxiliary overhaul marineengine

Engine chain man marine tightening drive stroke shaft camshaft procedure speed cam timing crankshaft rotational main pump ijin limited valve. The common causes of marine engine failure?

How To Service Your Marine Diesel Engine - Practical Boat Owner In 2021

www.pinterest.jp

www.pinterest.jp owner

Propulsion biodiesel combustion hydrogen engineeringlearn. Marine maneuvering engine emergency local engineers machinery engineer diesel ship engineering ships engines running inside room system marineinsight things breaking

Boat engine captain operating prepared engines well if. Common marine engine issues. Compressed air engine starting procedure of a marine engine

Post a Comment for "Marine Engine Change Over Procedure Fuel Oil For Ship's Main And Auxiliary Engines"