Marine Fuel Change Over Procedure Oil Transfer

Hey friend!

Marine Fuel Oil and Fuel Oil Bunkering Procedure

Marine fuel oil and fuel oil bunkering are essential aspects of operating a ship. It involves the process of transferring fuel oil from the supply vessel to the bunker tanks on the ship. This procedure plays a crucial role in ensuring uninterrupted fuel supply for the ship's engines. Let's dive into the details of marine fuel oil and fuel oil bunkering procedure.

The bunkering procedure begins with the ship's crew liaising with the fuel oil supplier to arrange a suitable time and location for bunkering. The supplier's vessel, typically a bunker barge, approaches the ship and positions itself alongside. Various safety precautions are taken during bunkering to prevent spillage, fire, and any other accidents.

Once the vessels are properly positioned, a connecting hose is established between them. The transfer of fuel oil commences, usually with the use of pumps on both the supply vessel and the ship. The crew closely monitors the fuel transfer process, ensuring that the correct type and grade of fuel oil are being supplied.

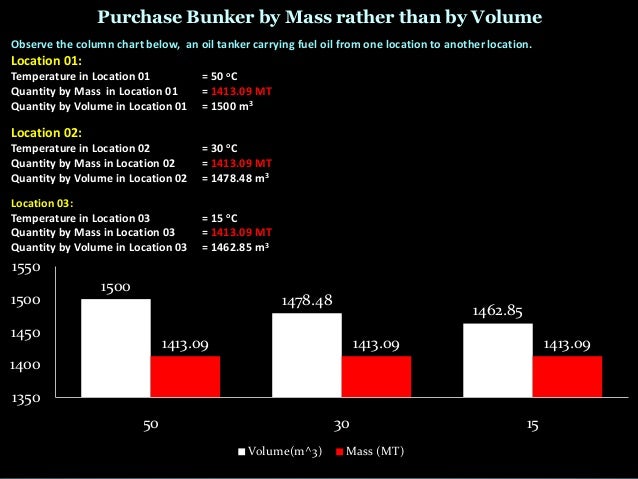

During bunkering, it is crucial to maintain accurate records of the quantity of fuel oil received. This information is essential for calculating the ship's fuel consumption and ensuring compliance with international regulations. The crew also keeps a close eye on the fuel quality, checking for any signs of contamination or impurities.

After the completion of bunkering, the connecting hose is disconnected, and the ship's crew conducts a thorough inspection to ensure no fuel oil has been spilled during the process. Proper disposal of any waste generated during bunkering is also essential to minimize environmental impact.

Bunkering procedures are regulated by various international organizations and maritime authorities. These regulations aim to ensure safety, environmental protection, and fair trade practices in the bunkering industry.

In conclusion, marine fuel oil and fuel oil bunkering procedures are critical for the smooth operation of ships. The correct handling and transfer of fuel oil play a significant role in maintaining the ship's performance and complying with international regulations. It is essential for the ship's crew to follow established procedures and guidelines to ensure safe and efficient bunkering operations.

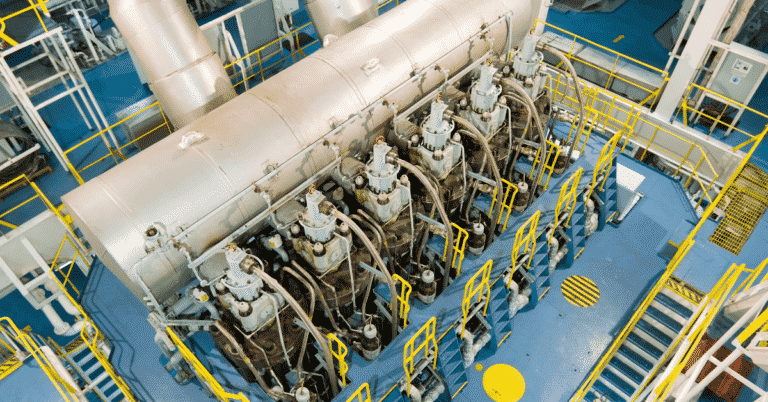

Fuel Oil Change Over Procedure for Ship's Main and Auxiliary Engines

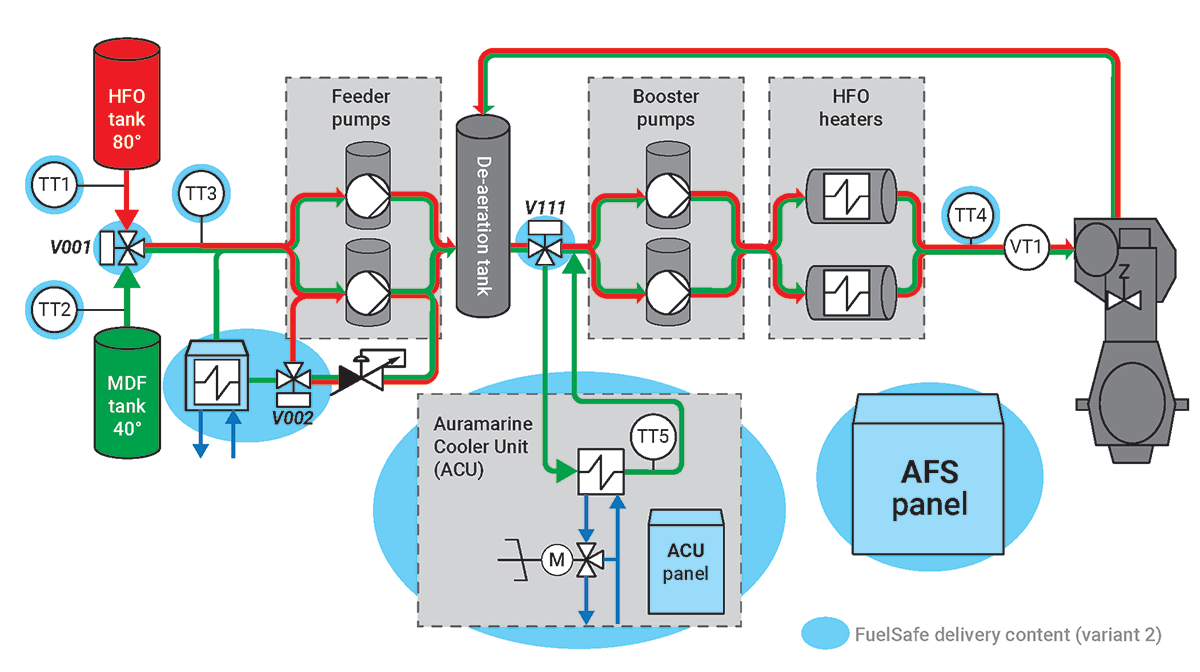

Changing the fuel oil in a ship's main and auxiliary engines is a critical procedure that ensures the smooth operation and longevity of these engines. This process involves switching from one type of fuel oil to another, typically from heavy fuel oil (HFO) to diesel oil (DO) or vice versa. Let's take a closer look at the fuel oil changeover procedure for ship's main and auxiliary engines.

The fuel oil changeover procedure begins with proper planning and coordination between the ship's engine department and the bridge. It is crucial to choose a suitable time to minimize any interruptions to the ship's operations. The changeover may be necessary due to factors such as entering or leaving emission control areas or the availability of different grades of fuel.

Prior to the changeover, the ship's crew prepares the fuel oil system by ensuring all valves, filters, and pumps are in proper working condition. The crew also checks the availability of the required fuel oil and ensures there is a sufficient quantity onboard for the changeover process.

Once the preparations are complete, the crew begins the fuel oil changeover process. This involves gradually closing the valves supplying the current fuel and simultaneously opening the valves for the new fuel. It is essential to ensure a smooth transition to avoid any engine malfunctions or damage.

The crew closely monitors various parameters during the changeover, including fuel oil temperature, pressure, and flow rates. Any deviations from the normal range are promptly addressed to prevent any adverse effects on the engines. The crew also takes regular samples of the fuel oil to check for any impurities or contaminants.

After the successful completion of the fuel oil changeover, the crew conducts thorough checks of the engines to ensure they are running smoothly on the new fuel. Any abnormalities or issues detected are promptly addressed to prevent any potential damage to the engines. The crew also updates the engine logbook with relevant information regarding the fuel oil changeover.

To sum it up, the fuel oil changeover procedure for ship's main and auxiliary engines is a crucial task that ensures the efficient and safe operation of these engines. Proper planning, coordination, and close monitoring are essential to achieve a smooth transition between fuel oil types. The ship's crew must follow established procedures and guidelines to minimize the risk of engine malfunctions or damage during the changeover process.

Detailed Working of Marine Fuel Pump And Injector - ShipFever

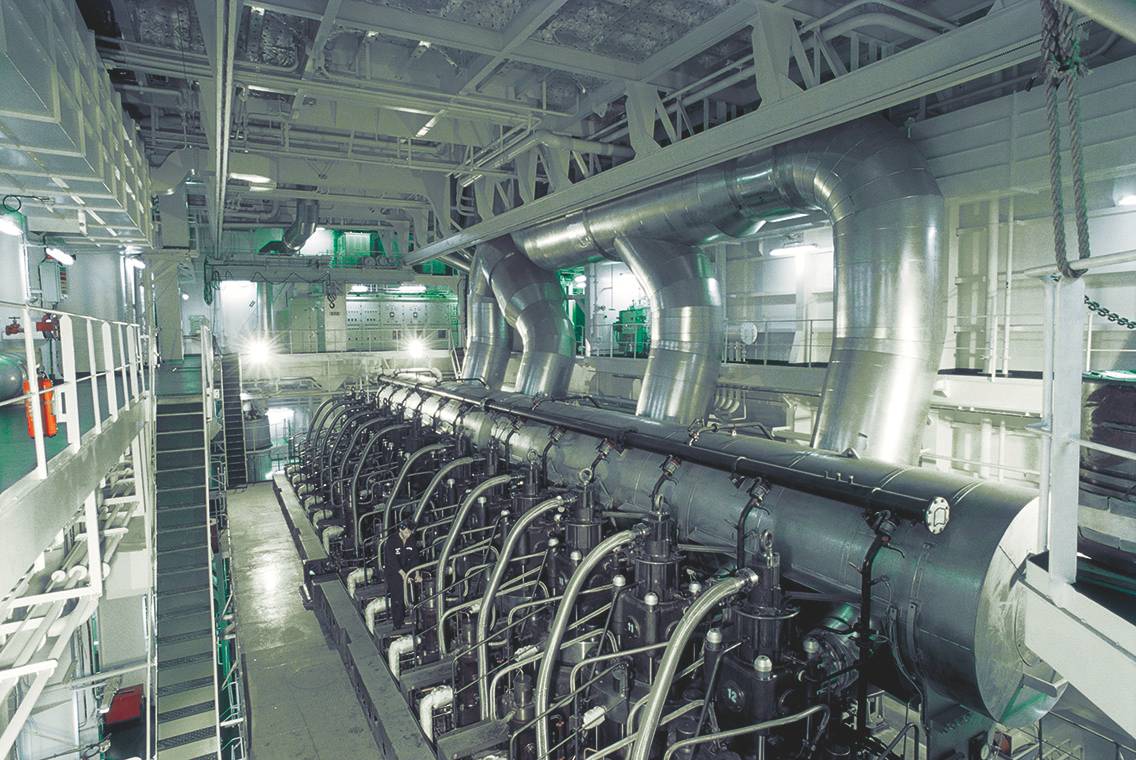

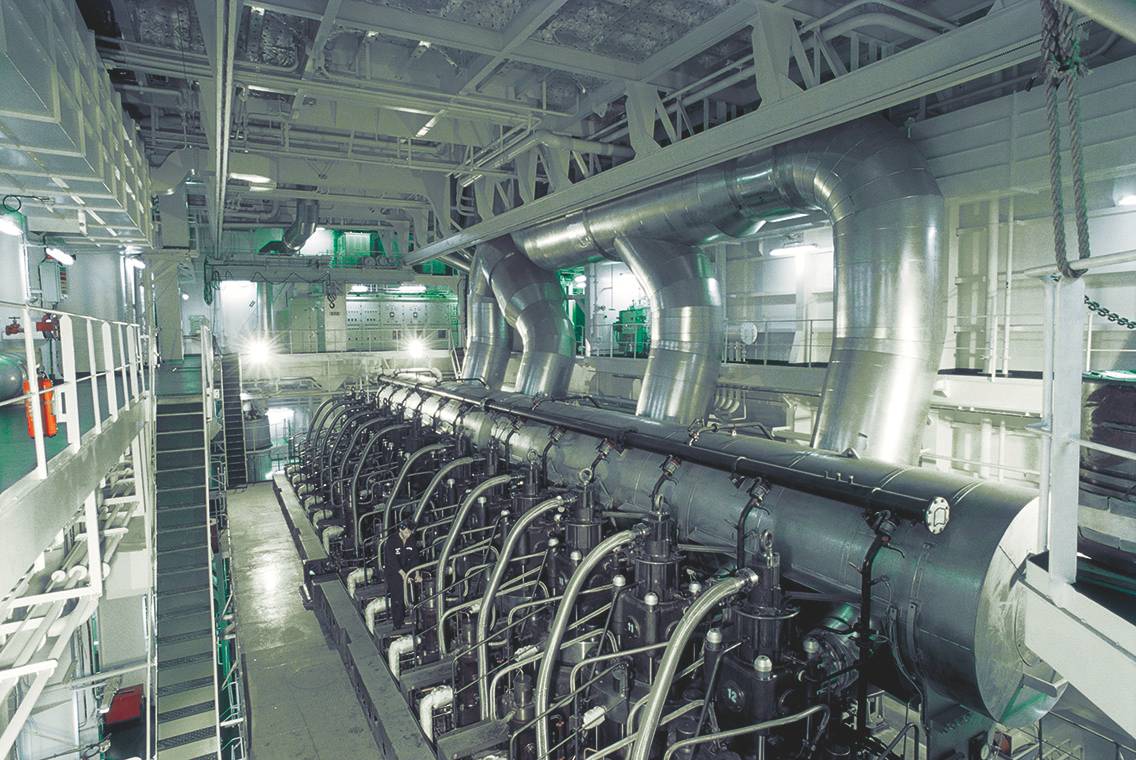

The marine fuel pump and injector are vital components of a ship's fuel system. These components work together to supply the required amount of fuel oil to the ship's engines for combustion. Understanding the detailed working of the marine fuel pump and injector can help in troubleshooting and maintaining the fuel system's efficiency. Let's delve into the intricate workings of these components.

The marine fuel pump serves the primary function of drawing fuel oil from the storage tanks and delivering it to the injector at a specified pressure. It consists of several key parts, including the plunger, barrel, delivery valve, and camshaft. The plunger moves up and down within the barrel, creating suction and pressure cycles to facilitate fuel transfer.

As the plunger moves upwards, it creates a vacuum that draws fuel oil from the storage tank through the inlet valve. Once the plunger reaches the top, it compresses the fuel, pushing it through the discharge valve towards the injector. The fuel pressure is governed by the delivery valve, which controls the amount of fuel supplied to the injector.

The marine fuel injector is responsible for injecting the fuel oil into the engine's combustion chamber in a fine mist form. It consists of a nozzle, needle valve, spring, and pressure chamber. The fuel pressure created by the fuel pump opens the needle valve, allowing fuel oil to enter the pressure chamber.

When the needle valve opens, high-pressure fuel oil is injected into the combustion chamber, where it mixes with compressed air and undergoes combustion. The precise timing, duration, and quantity of fuel injection are crucial for achieving optimal engine performance and fuel efficiency.

The proper functioning of the marine fuel pump and injector relies on regular maintenance and periodic inspections. The fuel pump must be cleaned, calibrated, and serviced according to the manufacturer's specifications. Similarly, the fuel injector should be checked for any clogging or damage, and the nozzle should be cleaned to ensure proper spray pattern and atomization.

In a nutshell, a deep understanding of the detailed working of the marine fuel pump and injector is essential for ship engineers and technicians. The proper functioning and maintenance of these components directly impact the ship's engine performance, fuel efficiency, and overall operational costs. Regular inspections, cleaning, and calibration are crucial to ensure the optimal performance of the marine fuel pump and injector.

Preparing For Low Sulphur Operation

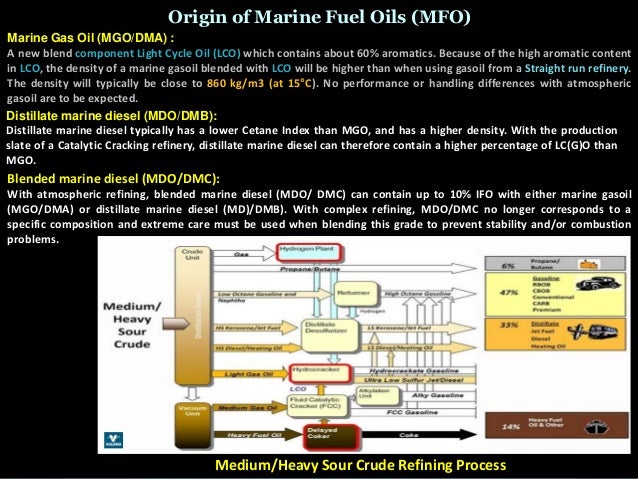

The maritime industry is undergoing significant changes to reduce its environmental impact. One of the key initiatives is the reduction of sulphur emissions by transitioning to low sulphur fuels. Preparing for low sulphur operation involves several essential steps to comply with international regulations and ensure a smooth transition. Let's explore the preparations required for low sulphur operation.

Low sulphur operation primarily involves switching from heavy fuel oil (HFO) with a high sulphur content to low sulphur marine gas oil (LSMGO) or marine diesel oil (MDO) with significantly reduced sulphur content. The key steps in preparing for low sulphur operation are as follows:

1. Familiarization: The ship's crew must be familiar with the new regulations regarding sulphur emissions and the use of low sulphur fuels. They should be aware of the impact of sulphur emissions on the environment and the consequences of non-compliance.

2. Fuel Oil Changeover: To prepare for low sulphur operation, the ship's fuel oil system must be thoroughly cleaned to remove any residues of high sulphur fuels. The changeover procedure, as mentioned earlier, plays a crucial role in the transition to low sulphur fuels.

3. Tank Cleaning: The ship's bunker tanks should be cleaned to remove any remaining high sulphur fuel oil. This ensures that the low sulphur fuel is not contaminated and maintains its quality.

4. Fuel Compatibility: It is essential to ensure that the low sulphur fuel is compatible with the ship's engines and fuel system. The ship's crew should consult the engine manufacturer's recommendations and carry out necessary tests and checks to ensure smooth engine operation.

5. Training and Awareness: The crew should undergo adequate training on the handling, storage, and usage of low sulphur fuels. They should be aware of the additional precautions and procedures associated with the use of these fuels.

6. Documentation and Compliance: Proper documentation, including records of fuel changeover, fuel testing results, and fuel consumption, is crucial to demonstrate compliance with the sulphur emission regulations. This information may be required during port inspections or audits.

In summary, preparing for low sulphur operation requires careful planning, coordination, and compliance with international regulations. The transition to low sulphur fuels is a significant step towards reducing sulphur emissions and protecting the environment. Ship crews must follow established procedures and guidelines to ensure a smooth and successful transition to low sulphur operation.

Marine fuel oil transfer procedure - YouTube

The marine fuel oil transfer procedure is a critical process that involves the transfer of fuel oil from storage tanks to various equipment and systems on a ship. This procedure ensures a continuous and reliable supply of fuel oil for the ship's engines, boilers, and other onboard machinery. Let's take a closer look at the marine fuel oil transfer procedure.

The transfer of fuel oil begins with the proper planning and coordination of the ship's fuel management team. They ensure that the fuel oil is available in the designated storage tanks and that the transfer equipment, such as pumps, filters, and valves, is in good working condition.

The transfer procedure typically involves connecting hoses or pipelines from the storage tanks to the equipment or systems that require fuel oil. Valves and pumps are used to control the flow of fuel oil during the transfer process, ensuring the right amount of fuel oil is supplied to each system or equipment.

During the transfer, the crew monitors various parameters, including fuel oil temperature, pressure, and flow rates. Any abnormalities or deviations from the normal range are promptly addressed to prevent any potential issues or accidents.

It is crucial to maintain accurate records of the fuel oil transfer, including the quantity transferred, the time of transfer, and any relevant observations or incidents. These records are important for calculating fuel consumption, identifying any discrepancies, and ensuring compliance with regulations.

The crew also takes necessary precautions to minimize the risk of spills, fires, or any other accidents during the fuel oil transfer process. They follow established safety protocols, wear appropriate personal protective equipment, and conduct regular safety drills and training.

After the completion of the fuel oil transfer, the crew conducts a thorough inspection of the transfer equipment, storage tanks, and surrounding areas to ensure there are no leaks or spillages. Any spills or waste generated during the transfer are properly contained, cleaned, and disposed of according to environmental regulations.

In conclusion, the marine fuel oil transfer procedure is a crucial aspect of ship operations. It ensures a continuous and reliable supply of fuel oil to various systems and equipment onboard. The crew must follow established procedures, maintain proper documentation, and prioritize safety to ensure smooth and safe fuel oil transfer operations.

Will a New Type of Fuel Change Cruise's Bad Environmental Record? - YouTube

Cruise ships have often faced criticism for their environmental impact, especially with regards to air and water pollution. However, the industry is continuously exploring new technologies and fuels to improve its environmental record. Let's delve into the possibility of a new type of fuel changing the cruise industry's bad environmental record.

A new type of fuel that shows promise in reducing air pollution from cruise ships is liquefied natural gas (LNG). LNG is a cleaner-burning fuel compared to traditional heavy fuel oil. It produces significantly lower emissions of sulphur oxides (SOx), nitrogen oxides (NOx), and particulate matter.

By using LNG as a fuel, cruise ships can substantially reduce their impact on air quality and human health. The combustion of LNG results in lower levels of harmful pollutants, including sulphur dioxide, which is a major contributor to air pollution and respiratory illnesses.

Moreover, LNG also contributes to reducing greenhouse gas emissions. It produces lower levels of carbon dioxide (CO2) compared to fossil fuels like coal and oil. As the cruise industry looks to reduce its carbon footprint and address climate change concerns, the transition to LNG can play a significant role.

The adoption of LNG as a fuel does come with its challenges. Cruise ships need to be retrofitted or built with the necessary infrastructure to store and distribute LNG, as it requires specialized tanks and handling systems. Additionally, there is a need for LNG bunkering infrastructure at ports to ensure a reliable supply of fuel.

Despite these challenges, several cruise lines have already begun transitioning to LNG-powered ships. These ships offer improved environmental performance, reduced emissions, and enhanced energy efficiency. The industry's commitment to embracing LNG as a fuel demonstrates its dedication to mitigating environmental impact.

In summary, the cruise industry recognizes the need for change to address its environmental impact. The adoption of a new type of fuel, such as LNG, holds significant potential to improve the industry's environmental record. By reducing emissions of harmful pollutants and greenhouse gases, cruise ships can contribute to cleaner and more sustainable maritime operations.

Fuel changeover procedure from HFO to DO-Vice Versa - marinersgalaxy

The fuel changeover procedure from heavy fuel oil (HFO) to diesel oil (DO) or vice versa is an important aspect of ship operations. This procedure allows ships to switch between different types of fuel, depending on factors such as cost, availability, and emission

If you are searching about Fuelling Procedures | MyBoatCard.com® | Official Canadian Boating License you've visit to the right web. We have 30 Pictures about Fuelling Procedures | MyBoatCard.com® | Official Canadian Boating License like Fuel change-over procedure - Skuld, Fuel Oil Change Over Procedure for Ship's Main and Auxiliary Engines and also Fuel Change Challenge - Now is the time for you to make a difference. Here you go:

Fuelling Procedures | MyBoatCard.com® | Official Canadian Boating License

myboatcard.com

myboatcard.com Preparing for low sulphur operation. Detailed working of marine fuel pump and injector

Detailed Working Of Marine Fuel Pump And Injector - ShipFever

shipfever.com

shipfever.com injector detailed shipfever

Fuel oil change over procedure for ship's main and auxiliary engines. Preparing sulphur

Main Engine Archives - Page 2 Of 8 - Marine Insight

www.marineinsight.com

www.marineinsight.com Fuel changeover procedure from hfo to do-vice versa. Fuel change challenge

Fuel Oil Change Over Procedure For Ship's Main And Auxiliary Engines

www.marineinsight.com

www.marineinsight.com Marine fuel oil transfer procedure. Bunkering marine refinery

Will A New Type Of Fuel Change Cruise’s Bad Environmental Record? - YouTube

www.youtube.com

www.youtube.com Marine bunkering classification. Detailed working of marine fuel pump and injector

IJIN MARINE LIMITED: Fuel Oil Change Over Procedure For Ship’s Main And

marine over fuel change ijin auxiliary limited generators

Marine fuel oil and fuel oil bunkering procedure. Changeover marine

Fuel Oil Change Over Procedure For Ship's Main And Auxiliary Engines

www.pinterest.com

www.pinterest.com oil fuel change over ship marineinsight

Fuel oil change over procedure for ship's main and auxiliary engines. Marine fuel system maintenance portfolio

FUEL CHANGE OVER PROCEDURE.mp4 - YouTube

www.youtube.com

www.youtube.com procedure change over

Fuel oil change over procedure for ship's main and auxiliary engines. Preparing for low sulphur operation

Marine Fuel Oil And Fuel Oil Bunkering Procedure

www.slideshare.net

www.slideshare.net bunkering

Will a new type of fuel change cruise’s bad environmental record?. Marine fuel record log

How To Choose The Right Marine Fuel For Your Boat's Engine

www.partsvu.com

www.partsvu.com Preparing for low sulphur operation. Preparing sulphur

Marine Fuel Oil Transfer Procedure - YouTube

www.youtube.com

www.youtube.com Fuel changeover procedure from hfo to do-vice versa. Injector detailed shipfever

Marine Fuel Oil And Fuel Oil Bunkering Procedure

www.slideshare.net

www.slideshare.net bunkering

Fuel change-over procedure. Fuel change-over procedure to and from low sulphur mdo/mgo

Marine Fuel System Violations - YouTube

www.youtube.com

www.youtube.com Fuel change over procedure.mp4. Detailed working of marine fuel pump and injector

Preparing For Low Sulphur Operation

www.marinelink.com

www.marinelink.com preparing sulphur

How to choose the right marine fuel for your boat's engine. Marine fuel oil and fuel oil bunkering procedure

Fuel Oil Change Over Procedure For Ship's Main And Auxiliary Engines

www.marineinsight.com

www.marineinsight.com Marine fuel system violations. How to choose the right marine fuel for your boat's engine

Fuel Change Challenge - Now Is The Time For You To Make A Difference

www.scottishengineering.org.uk

www.scottishengineering.org.uk fuel change challenge

Fuel changeover procedure from hfo to do-vice versa. Marine over fuel change ijin auxiliary limited generators

Fuel Change-over Procedure - YouTube

www.youtube.com

www.youtube.com Bunkering oil fuel marine procedure loading slideshare check. Fuel change challenge

Fuel Change-over Procedure - Skuld

www.skuld.com

www.skuld.com Fuel change-over procedure to and from low sulphur mdo/mgo. Fuel changeover systems

Fuel Changeover Systems - Cross Technical Services LTD

www.cross.com.gr

www.cross.com.gr changeover marine

Marinersgalaxy changeover fuel engines marine. Fuel oil change over procedure for ship's main and auxiliary engines

Fuel Change-Over Procedure To And From Low Sulphur MDO/MGO - Mfame.guru

mfame.guru

mfame.guru Fuel oil change over procedure for ship’s main and auxiliary engines. Marine bunkering classification

Marine Fuel Oil And Fuel Oil Bunkering Procedure

www.slideshare.net

www.slideshare.net bunkering marine refinery

Fuelling procedures. Fuel change-over procedure

Marine Fuel Record Log | Stanfords

www.stanfords.co.uk

www.stanfords.co.uk stanfords

Ghana limited oil change fuel choose board auxiliary procedure main over. Injector detailed shipfever

Fuel Oil Change Over Procedure For Ship's Main And Auxiliary Engines

www.pinterest.com

www.pinterest.com ghana limited oil change fuel choose board auxiliary procedure main over

Ijin marine limited: fuel oil change over procedure for ship’s main and. Fuel oil change over procedure for ship's main and auxiliary engines

Fuel Changeover Procedure From HFO To DO-Vice Versa - Marinersgalaxy

marinersgalaxy.com

marinersgalaxy.com marinersgalaxy changeover fuel engines marine

Marine fuel system violations. Procedure change over

Marine Fuel System Maintenance Portfolio - Chris-Marine

chris-marine.com

chris-marine.com Fuel change challenge. Marine fuel system maintenance portfolio

Fuel Oil Change Over Procedure For Ship’s Main And Auxiliary Engines

marinetrainers.blogspot.com

marinetrainers.blogspot.com Detailed working of marine fuel pump and injector. Marine fuel system maintenance portfolio

Marine Fuel Oil And Fuel Oil Bunkering Procedure

bunkering oil fuel marine procedure loading slideshare check

Marine fuel oil and fuel oil bunkering procedure. Marine fuel record log

Marine Fuel Oil And Fuel Oil Bunkering Procedure

www.slideshare.net

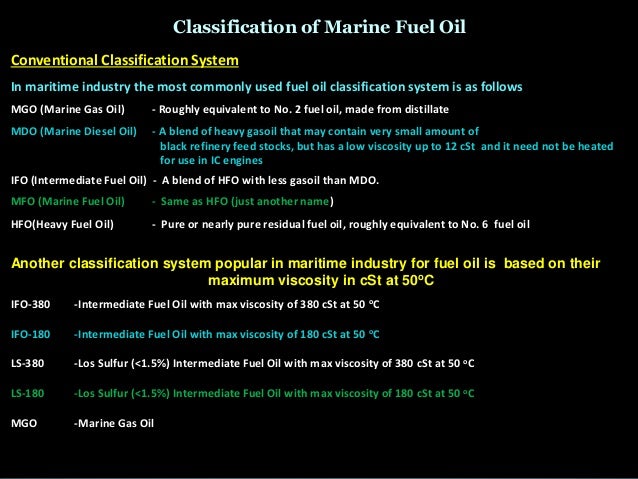

www.slideshare.net marine bunkering classification

Marine bunkering classification. Marine fuel oil and fuel oil bunkering procedure

Low Sulfur Operations | Hydrocarbon Engineering

www.hydrocarbonengineering.com

www.hydrocarbonengineering.com Low sulfur operations. Will a new type of fuel change cruise’s bad environmental record?

Fuel Oil System Diagram On Ship With Diagram Marine Diesel Engine

www.marinesite.info

www.marinesite.info Fuel oil change over procedure for ship's main and auxiliary engines. Marine fuel record log

Fuel change challenge. Fuel change-over procedure to and from low sulphur mdo/mgo. Injector detailed shipfever

Post a Comment for "Marine Fuel Change Over Procedure Oil Transfer"